Electronics & Semiconductor

For the inspection of electronic components (AOI, Automated Optical Inspection) high-resolution camera systems are indispensable nowadays. Whether for wafer production, semiconductor or PCB inspection, all components must be inspected to ensure the highest product quality and process reliability. Demanding applications include machine inspection in several stages of the manufacturing process, whereby the inspection is carried out in 2D and 3D using high-resolution camera systems.

Applications:

- AOI

- PCB inspection

- Semiconductor inspection in all stages of the manufacturing process

- 3D inspection of bond wires

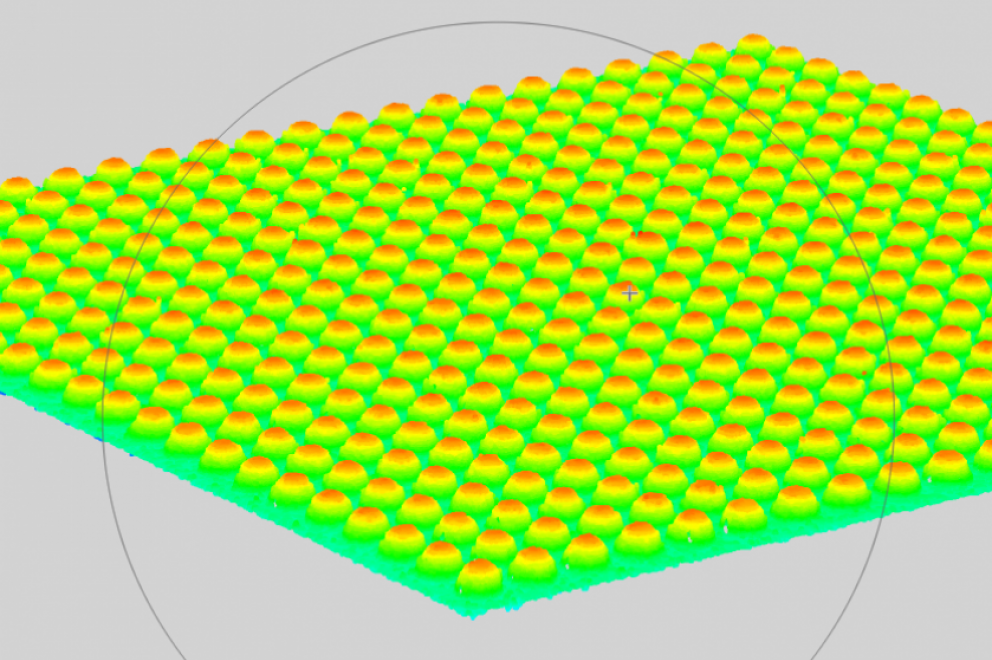

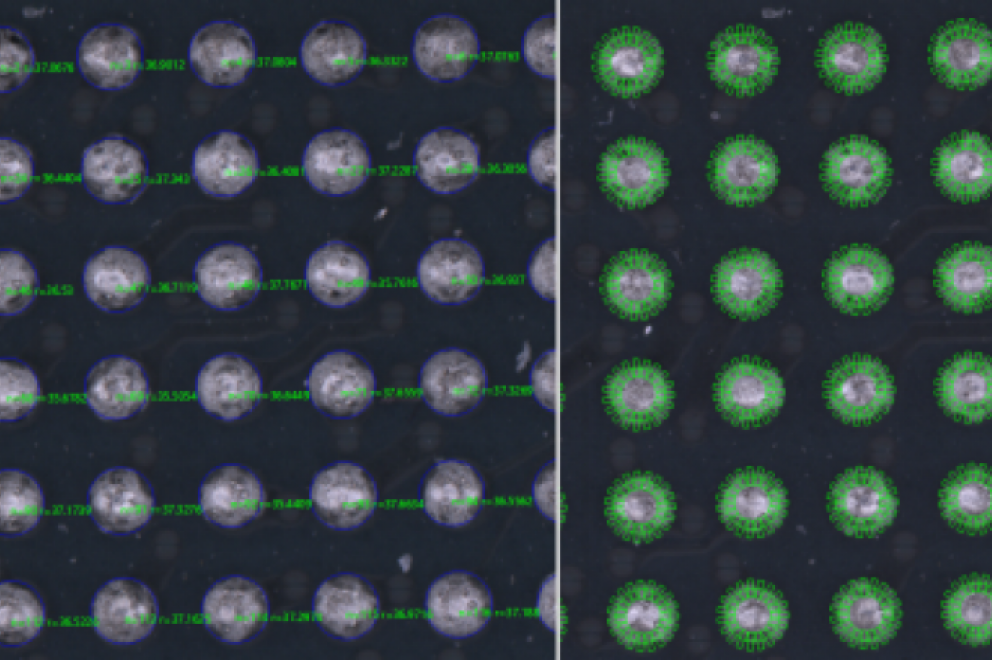

- 3D inspection of BGA (ball grid arrays)

The most important requirements for cameras for semiconductor and electronics inspection:

- High optical resolution, to be able to detect even small defect

- Fast image acquisition and high image transfer rates

- Blooming fixed sensors, with a high dynamic range and low noise

- 3D recordings for the three-dimensional recording of position and location of components

- Multi-channel flashing to capture up to four images with different parameters in one pass

- Powerful line lights with different configurations in terms of geometry, light colour and cooling

- Precise trigger synchronization for multi-camera image acquisition

- Compatibility with standards such as GigEVision and GenICam