Case Studies

Future-proof Print Inspection at CCL Label

With increasing requirements and rising cost pressures, traditional control methods in label printing are quickly reaching their limits. CCL Label is breaking new ground: the label printer is relying on an innovative vision system that detects errors early on, reduces waste, and increases sustainability and process reliability.

Battery Electrode Foil Inspection

In lithium-ion battery production, inspecting anode and cathode foils is crucial for quality and efficiency. Challenges include detecting defects in high-speed, high-resolution settings.

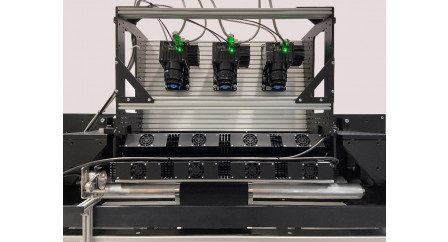

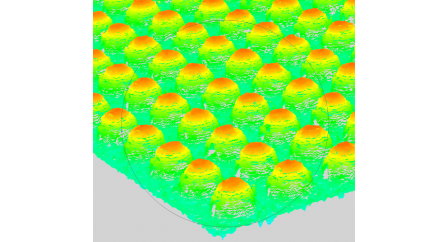

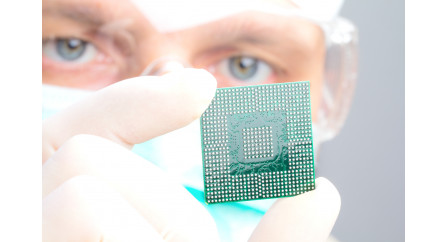

3DPIXA wave for BGA inspection

In the electronics and semiconductor industry soldering connections using BGAs (Ball Grid Arrays) are widespread. Most prominent examples are the mounting of microprocessors.The only way to ensure this is a one hundred percent inspection, where each solder ball must be measured three-dimensionally.

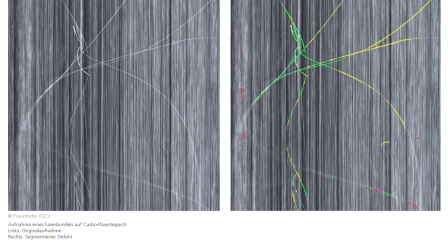

Analyzing textures in fiber technology

Online testing of fibers can be a challenge for measurement technology providers. Together with industrial partners, the staff of the Fraunhofer IGCV has succeeded in reliably detecting fiber defects in production. Within the current project AirCarbon III, the Fraunhofer IGCV conducts research with AI in fiber technology.

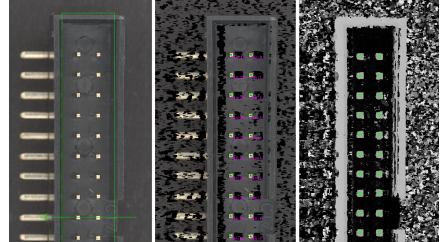

Connector pin inspection

This report isan example how to use a 3DPixa and the 3DAPI to implement a measuring task for connectors.

Line-based stereo vision system checks ball and roller bearings

Active Inspection - a leading US system integrator for image processing systems - has developed an inspection system for bearings based on Chromasens' 3DPIXA 3D stereo line scan camera that is characterized by high flexibility and high speed.

3D line scan camera - 3DPIXA for testing connectors

Connectors are indispensable in electronics. For a long time now, they can only be economically produced on fully automated production lines with an integrated 100% quality check. Eberhard AG achieves this quality goal by switching to a one-step contactless test method with 3D line scan cameras.

3D image capturing system for on-track train inspection

3D image capturing system for on-track train inspection. Setting the direction. In view of ever more complex railway networks and increasingly shorter cycles, the assurance of a fault-free function of railway vehicles is the highest priority of railway operators. The implementation of new measuring methods such as high-precision 3D image capturing systems offers new strategies for innovative maintenance concepts.

3D machine vision opens up new perspectives for AOI (Automated Optical Inspection)

Miniaturisation in the field of semiconductor technology proceeds unimpeded. The development of increasingly smaller components and integrated circuits requires not only extremely precise production processes, but also new, innovative methods of quality control. The use of high-resolution 3D line scan cameras is one method.