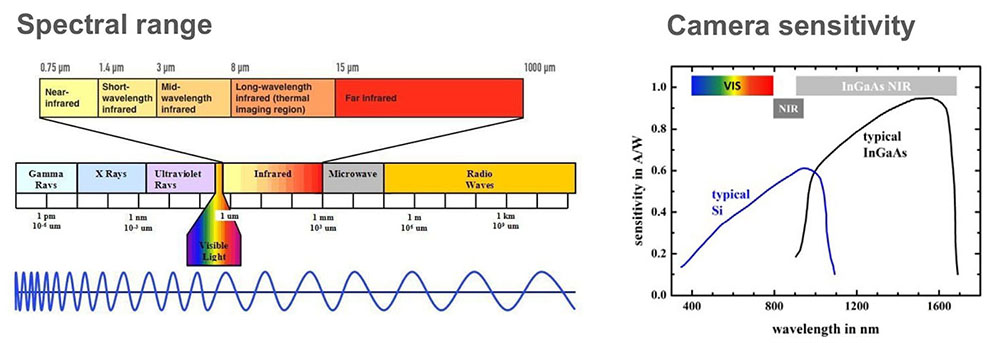

Shortwave infrared light (SWIR) is usually defined as light with a wavelength between 0.9 and 1.7 μm.

Because silicon becomes increasingly transparent above approx. 1000nm, other semiconductor materials must be used for SWIR image sensors to absorb photons in this wavelength range and convert them into electrons efficiently.

Indium gallium arsenide (InGaAs) is the most common material for SWIR image sensors.

Spectral sensitivity ranges depends on composition of the alloy and further parameters like cooling etc.

Applications and Materials

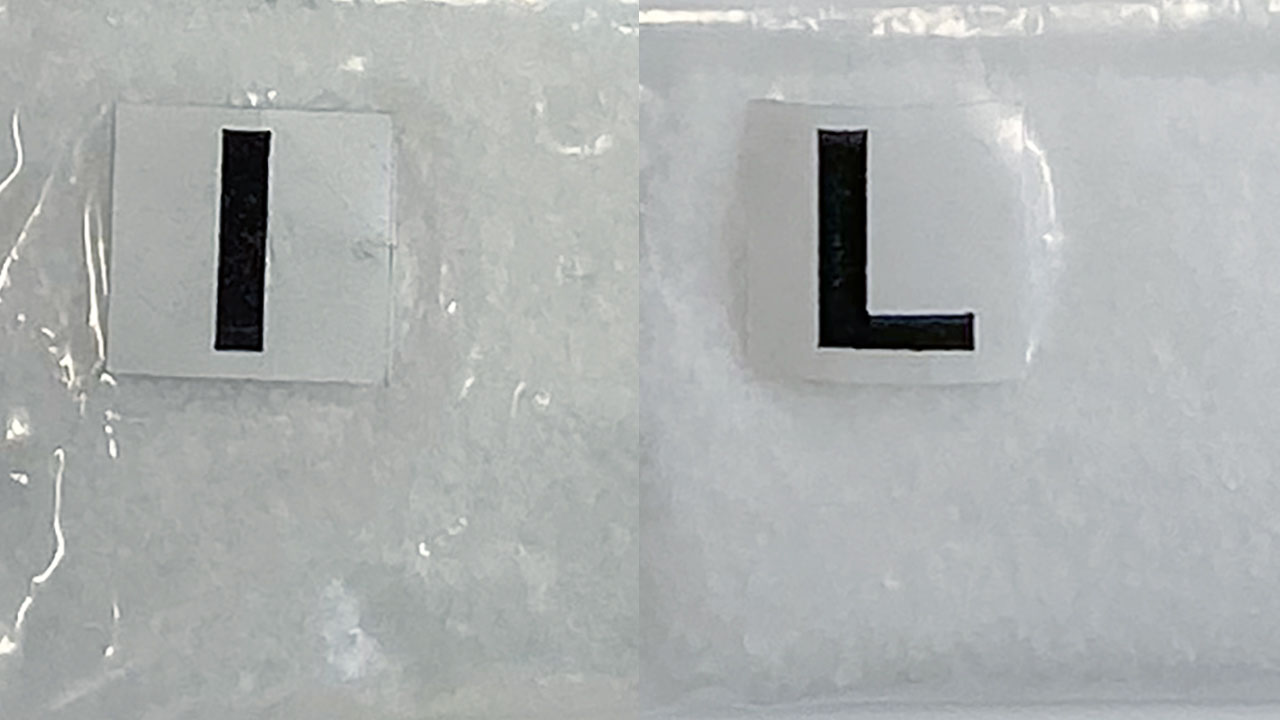

In the SWIR range the camera can see through many printing inks, plastic, silicon, packaging materials, and can thus be used for non-destructive testing.

For example, following inspection and sorting tasks can be carried out even through closed packaging:

- Fill Level Measurements

- Presence Checks

- Semiconductor Inspection

- Recycling

- Plastic Sorting

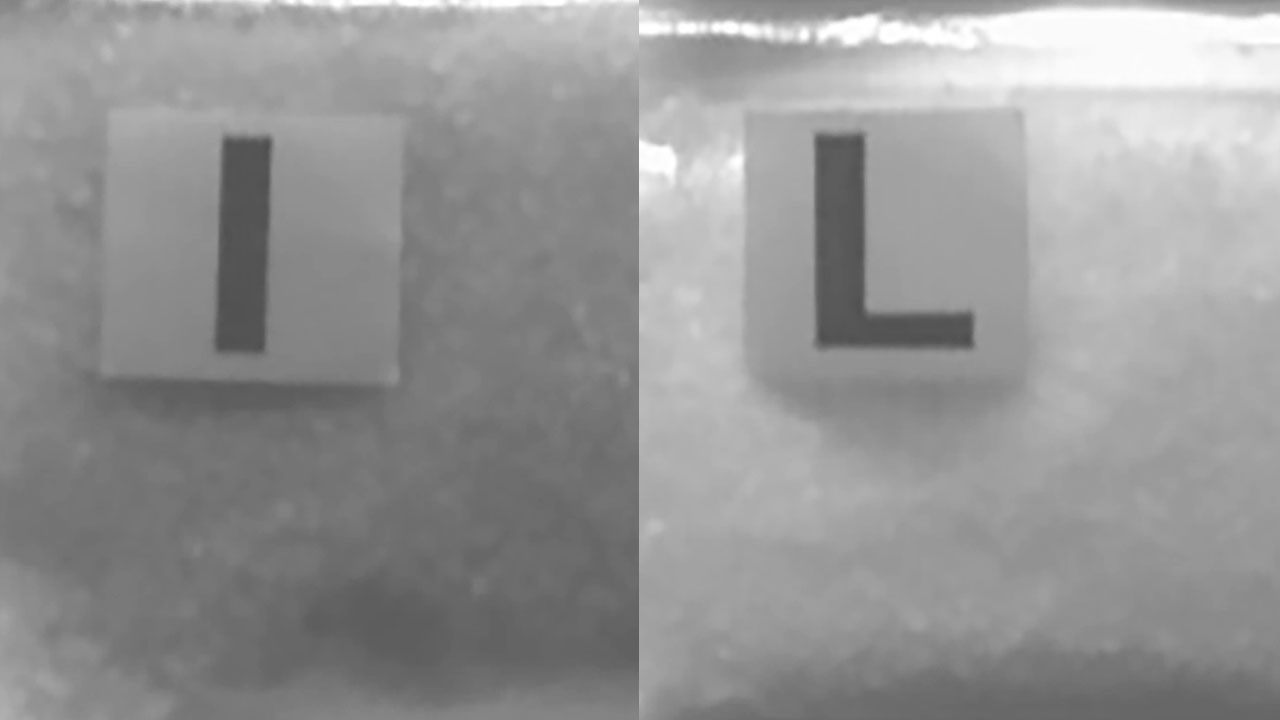

Perception of the

human eye

SWIR analysis at

1150 nm, 1200 nm & 1450 nm

Perception of the

human eye

SWIR image at 1100 nm

as grayscale

In this video you can see the allPIXA SWIR and Corona II illumination in a substance determination live demo at high speed:

allPIXA SWIR is the ideal solution for material identification, sorting of recycling materials, fruit, vegetables, seeds, grains and qualification of food. Contaminants and foreign objects (e.g. stones) in Seed & Grain Sorting can easily be detected.

Perception of the

human eye

SWIR image

stone detection

Moisture measurement in food

Humidity measurement is also a great help for qualification of food. In addition to the moisture content, the SWIR range can also be used to determine the sugar, starch, alcohol and acid content of many samples, for example, to determine the freshness or degree of ripeness of food or detect bruises on fruits. Also several gases that are completely transparent in the visible range can be easily detected in the SWIR range.

Chromasens is offering a complete solution package with cameras and dark field LED illumination modules for fast inspection and sorting processes using SWIR technology.

For materials that differ in spectral range within the working range of a SWIR camera, narrowband LED light sources provide more homogeneous light distribution and better differentiation characteristics than broadband halogen light sources!

With their patented reflector technology, Chromasens' powerful LED systems offer higher radiant power than conventional halogen lights and thus very high efficiency with less image noise and more accurate inspection results in the recognition software.

LED lighting with a runtime of up to 25,000 operating hours means less downtime, less maintenance and thus lower service costs for the user.